- NEW DESIGN

- FASHION FABRIC

hello world

hello world

hello world

- MANUFACTURING

- RESOURCES

- SERVICE

- ABOUT US

- CONTACT

- NEW DESIGN

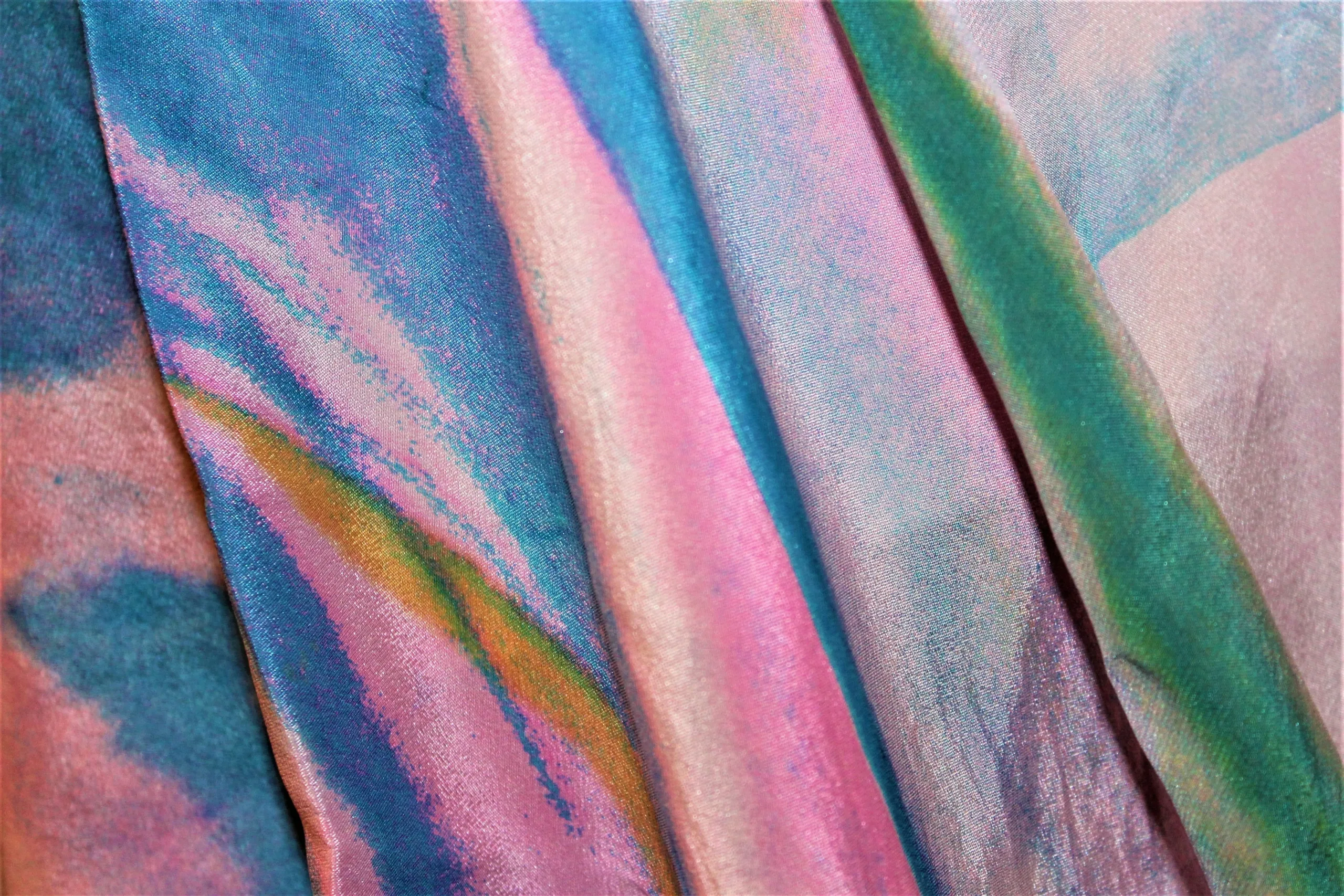

- FASHION FABRIC

hello world

hello world

hello world

- MANUFACTURING

- RESOURCES

- SERVICE

- ABOUT US

- CONTACT

SAILYIN MANUFACTURING

HIGH QUALITY STANDARDIZED PRODUCTION

NEVER COMPROMISE!!!

SAILYIN started to build up the foil stamping factory since 2007, and now we have more than 3000 styles and unique crafts, and we serve more than 50 apparel brands all over the world.

In addition, from 2019, SAILYIN has invested in sequins, hot drilling, embroidery, flocking and other processes, and we are still exploring new processes to create more great products.

FINISHING PROCESSES

When you choose SAILYIN, you gain the professional knowledge of the best talents in the industry, the combination of various leading processes, precise organization practices, and strict testing methods to meet our industry-leading standards.

TESTING

SAILYIN’s products ensure that the quality of all products meets the customer’s standards before shipment. Our production tracking personnel will track orders throughout the process and strictly follow the company’s production standards to ensure the consistency and stability of product quality;

At the same time, inspectors will conduct physical and chemical index testing on the head cylinder goods and bulk goods, and conduct a full quality inspection on all bulk goods, issuing inspection reports. They will also actively invite customer quality inspectors to our company’s quality inspection to ensure that every meter of goods shipped out meets customer standard requirements.

In short, the inspection department is responsible for ensuring that every meter of fabric send to our partners has first-class quality – they are really good at this.

SAILYIN is a young and dynamic company dedicated to high quality fabric production and testing systems since its inception in 2019. SAILYIN’s predecessor has specialized in the design and production of FOIL STAMPING for over 17 years, and is the preferred choice of many fashion brand suppliers.