- NEW DESIGN

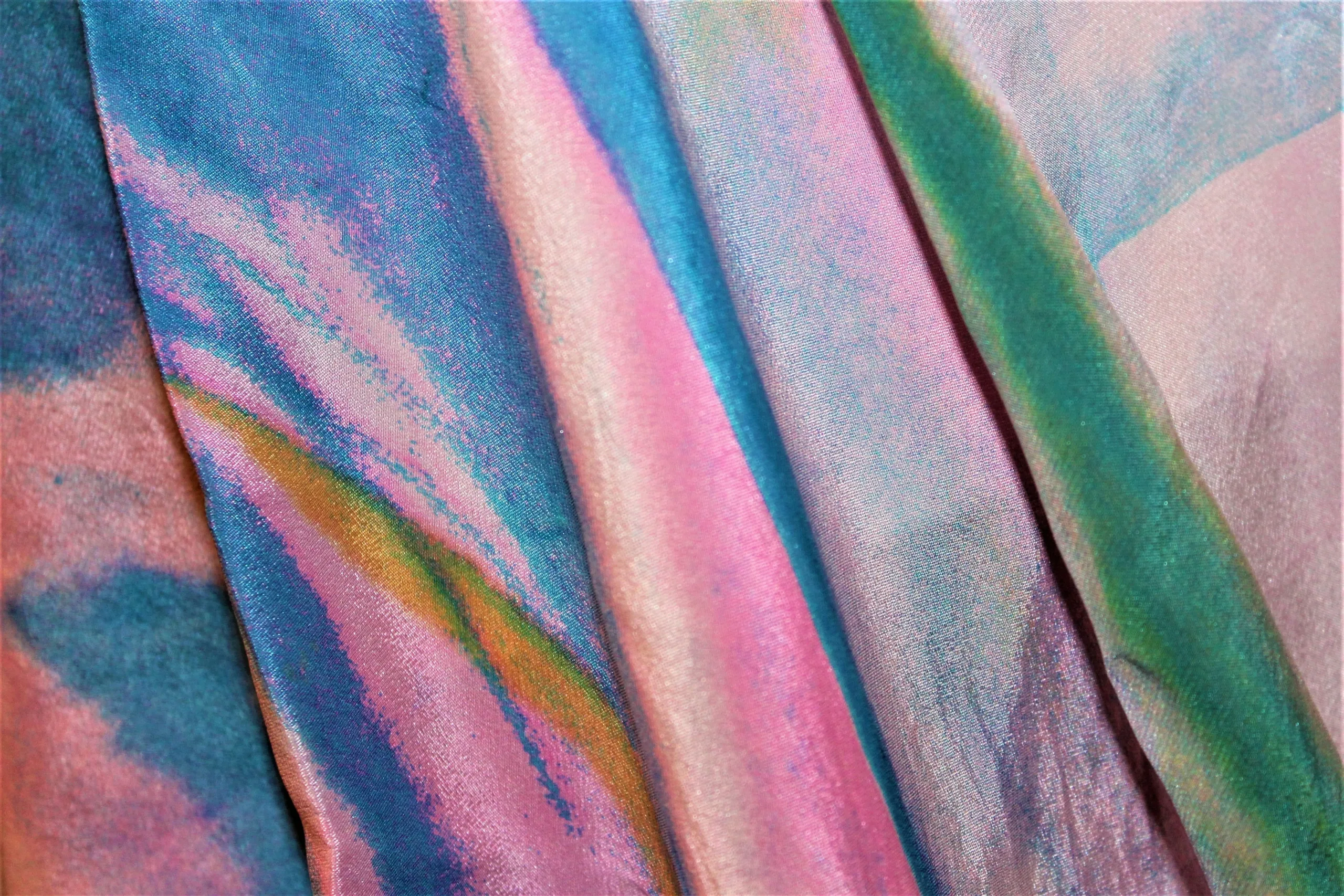

- FASHION FABRIC

hello world

hello world

hello world

- MANUFACTURING

- RESOURCES

- SERVICE

- ABOUT US

- CONTACT

- NEW DESIGN

- FASHION FABRIC

hello world

hello world

hello world

- MANUFACTURING

- RESOURCES

- SERVICE

- ABOUT US

- CONTACT

1. Process standardization

SAILYIN has formulated process standardization rules for business and production to standardize the service for every customer, and will provide timely feedback to customers on the progress, workmanship and error range in every procedure, so that customers can receive the most professional service in an easier and more concise way;

Production standardization rules so that production followers can simply and efficiently implement each order, to ensure that every detail will not be wrong, in the required time to complete the established tasks.

2. Standardization of finishing process

“In the era of uncertainty, let SAILYIN bring you quality certainty”, we use the model of data-driven production process.

Production followers will be samples, large goods of each production process of each step of the production details recorded in the detailed production process sheet, summarized into the production process data, and in the next production of the same samples, large goods as a basis for guidance, to determine the production process of each step of the details of the production process and the data of the production process is not wrong.

Ensure the consistency and stability of production quality, so that the production process can be traced, traceable, reviewable and reusable.

3. Quality control standardization

SAILYIN has strict quality control standards, with the goal of controlling all risks at the earliest stage.

We have a long-term strategic cooperation with SGS, BV and other international testing companies to conduct important physical and chemical indexes for each sample fabric and each big shipment to ensure that all the indexes are inline with the company’s and customer’s quality standards before production and shipment.

And all the sample fabrics, large goods for the quality of the whole inspection, will be every time the results of the quality inspection, test results, summarized into a quality inspection report, so that customers have a clear understanding of the quality of the fabrics before not receiving the goods!